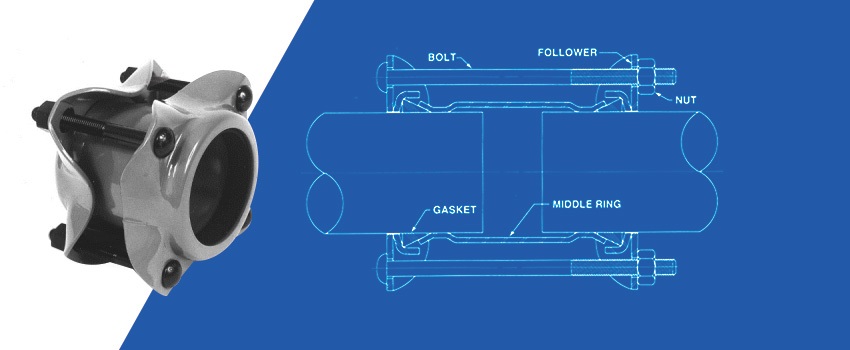

A Dresser coupling is a type of pipe fitting that connects two sections of pipe without using threads. It’s made up of a middle ring, two follower rings, gaskets, and bolts. Dresser couplings are used in industrial applications and are known for being leak-proof, corrosion resistant, and easy to install.

How it works

- The middle ring has a conical flare at each end to receive the gasket.

- The follower rings hold the outer ends of the gaskets.

- Tightening the bolts pulls the follower rings together, compressing the gaskets.

- This creates a flexible, leak-proof seal between the pipes.

Features

- Dresser couplings can be made from a variety of materials, including high-strength, low-alloy steel, stainless steel, and electro-galvanized steel.

- They can be used with pipes of different diameters.

- Dresser couplings can be used in a wide range of temperatures, from -20°F to +1200°F.

- They can be used with a variety of pressure ratings, up to 1500 PSI.

- Dresser couplings can be electrically insulated or non-insulated.

Dresser couplings create flexible, non-rigid pipeline joints accepting expansion, contraction, vibration and line deflection. • Sizes range from 1/2” through 120” to cover every application including high temperature or severe and abrasive line contents.