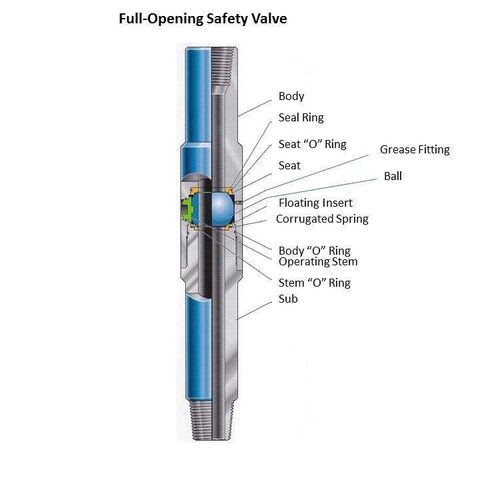

A Full Opening Safety Valve (FOSV), also known as a TIW valve, is a crucial, manual, ball-type valve used in oil and gas drilling to stop hazardous fluid flow up the drill string, ensuring well control by allowing quick insertion (stabbing) against high pressure when needed, featuring a large internal bore for minimal flow restriction and pressure resistance from both directions.

Key Features & Function:

- Ball Valve Design: Uses a rotating ball to open or close the flow path, providing a tight seal.

- Full Opening: The internal diameter is nearly the same as the drill pipe, preventing blockages and allowing tools to pass through.

- Bidirectional Pressure: Can withstand high pressures from either direction (downhole or from the surface).

- Manual Operation: Operated by a specialized wrench for quick closure during emergencies.

- Stabbing Capability: Designed to be rapidly inserted (stabbed) into the drill string to shut in a well during emergencies like kicks (uncontrolled influx of formation fluid).

When it’s Used:

- During Tripping: When pulling drill pipe out of the hole, the FOSV is kept open and ready on the rig floor.

- Emergency Well Control: If a kick occurs and the Kelly is disconnected, the FOSV is quickly stabbed into the drill string and closed to seal the wellbore.

Importance:

- It’s a fundamental piece of equipment for well control, preventing blowouts by giving drillers a fast way to seal the well against immense downhole pressures.